Green Building

In the building sector, huge amounts of mineral or petroleum based building materials, such as cement, concrete, building bricks, glass wool and expanded polystyrol, are used. Such materials have a high carbon footprint, health risks and other environmental problems.

Biobased building materials often have an improved environmental and health profile and even store CO2, which was captured by the plant during growth, during their useful lifetime (often +30 years). By using biobased building materials, carbon dioxide can be actively removed from the atmosphere, which is a strong leverage to manage atmosphere carbon dioxide content and to mitigate climate change.

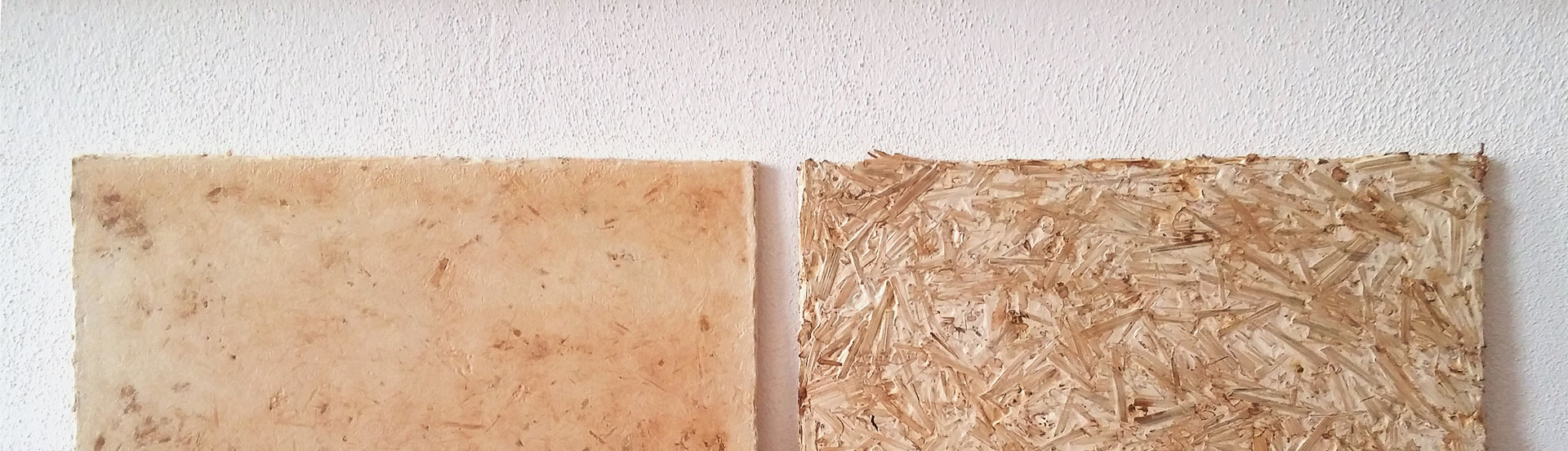

Formaldehyde-free binder for Particle Boards

AVA Biochem developed a formaldehyde-free binder for biobased particle boards on the basis of HMF and phenol. The binder has been successfully tested using miscanthus fibers provided by GRACE project partner GTK and will be further optimized for specific applications, including miscanthus fiber fractions, wood particles and wood fibers. The formaldehyde-free binder and the application conditions for this binder are further improved and a large commercialisation potential is seen in this novel product.

Mycellium-based Panels

Chopped miscanthus and hemp shives will be used to demonstrate the production of mycellium-based panels. The mycellium fungi is allowed to grow on the biomass until it is completely covered with mycel biomass. At this stage the panels are dried, pressed and sterilized. In this process the mycel is acting as a natural binder and no chemical additives are required. The final product is a completely natural, stable and sterile panel which can be used for packaging, furniture and building.

During the GRACE project, MOGU developed multiple applications and designs for this novel material, including sound absorption, interior design and insulation elements. The products are meanwhile available on the market and further commercialisation is ongoing.

Insulationmaterial

Miscanthus parenchym (pith) is seperated with a special separation machine from the surrounding, fibrous stem material. The fibrous biomass can be used for other applications, while the parenchym is mainly interesting as insulation material. The parenchym biomass contains a high number of closed pores and therefore has a similar structure like expanded styropor. This makes this biomass highly interesting to produce biobased insulation material with a very low thermal conductivity and replace fossil oil-based styropor for insulation purposes.

In GRACE, Gießertechnik Kühn (GTK) was building a demonstration plant for miscanthus fibre fractionation and demonstrated the full scale operation of this plant. The fractionation plant is able to sort miscanthus biomass in various fractions, including fractions interesting as insulation material, for fibre applications and fine fractions for paper production or 3D printing. GTK is commmercializing all fractions and working closely with other industrial partners to identify potential application for each fraction.

Lightweight Concrete

Miscanthus chips are further processed to homogenize the particle size for application in lightweight concrete. The very fine dust fraction is being removed, since it would negatively impact the product properties. The coarse fraction is used for production of lightweight concrete, while the fine dust fraction can be utilized as additive in speciality paper. Lightweight concrete has improved insulation properties than conventional concrete and can be used for non load-bearing applications, e.g. in wood or steel frame-construction. Further lightweight concrete helps to reduce the consumption of energy- and CO2-intensive cement.

In GRACE, Miscanthusgroep was successfully developing miscanthus preparations for lightweight concrete applications with different partners in the concrete industry. Miscanthus lightweight concrete applications are meanwhile available on the market, including pre-fabricated noise protection elements.

Funders

The GRACE project has received funding from the Bio-Based Industries Joint Undertaking (BBI JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 745012.

Bio based Industries Consortium

Bio based Industries Public-Private Parnership

European Union